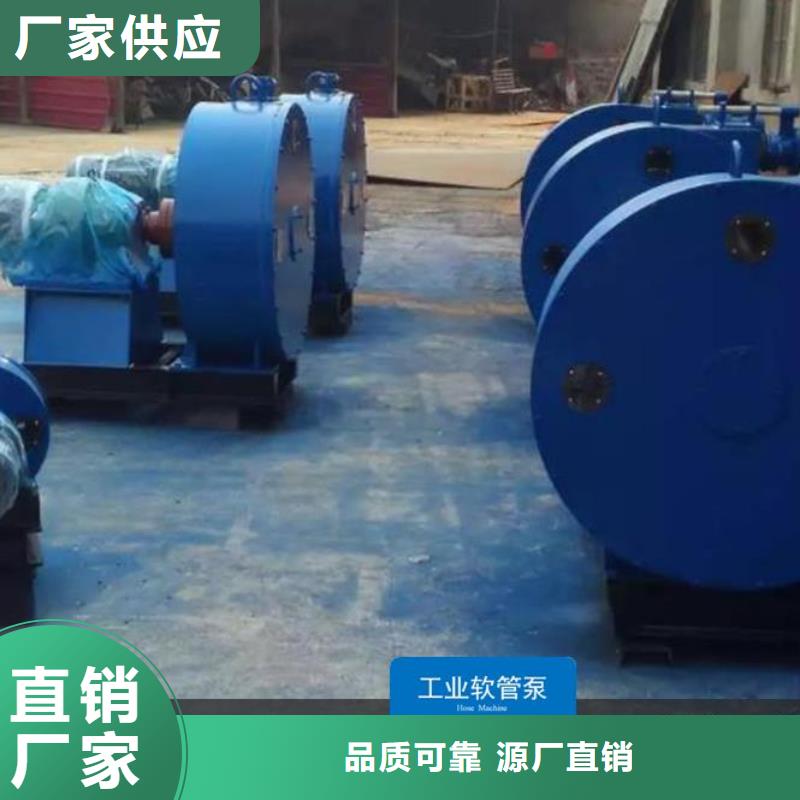

| 规格型号 | YXRG-15 (200) |

|---|---|

| 流量 | 2~85立方/小时 |

| 功率 | 1.5~35kw |

| 压力 | 1Mpa~2Mpa |

| 重量 | 60~2000kg |

| 水平输送能力 | 100m |

| 垂直输送 | 3~15m |

| 软管泵最大吸程 | 8m |

| 软管尺寸 | 按规格定制 |

| 设备类型 | 小型软管泵 |

| 设备用途 | 工业软管泵、输送软管泵 |

| 工作原理 | 滚轴挤压式循环往复 |

| 参考价格 | 5000~85000 |

| 耐腐蚀性输送性能 | 可输送 |

| 食品果酱输送性能 | 可升级为不锈钢型软管泵,食品级软管 |

| 其他行业应用 | 根据输送物质类型,定制设计加工 |

| 交货周期 | 小型软管泵现货,大型定制 |

| 付款方式 | 预付30%,剩余货到付清 |

豫信致诚机械设备有限公司长期致力于 安徽巢湖路面抛丸机的革新与开发,在生产实践当中积累了丰富的专业知识。吸收探索世界新发展动态优势,设计开发一系列高新智能 安徽巢湖路面抛丸机产品。踏实进取,开拓创新,充分利用高新技术,百折不挠地勇攀质量高峰,努力打造成为国际 安徽巢湖路面抛丸机产品,专业制造与诚信的服务,期待与全世界友人及同行进行广泛的合作与交流。

工业软管泵设备特性说明:部分特性说明。

(4)自吸力高。相对于其他形式的容积式泵比较,理论自吸高度可达到9.5m。一般渗滤液都在储液池中,需要高自吸力的泵将渗滤液吸上来,然后输送到过滤器或焚烧炉中。

(5)安装变频电机后,可根据实际需要处理的垃圾渗滤液的多少轻松的调节电机工作频率,可达到流量的线性变化。使得整个垃圾渗滤液回喷系统操作简单,自动化程度高。

(6)泵腔内部便于清洗。当不需要输送时,可打开进出口端的旁通管路可将软管内清洗干净,延长软管的使用寿命。

还有一种食品级橡胶软管泵,它的内衬的橡胶层需要达到了食品卫生的要求,同时也需要符合EHEDG或者其他卫生级的要求。还有三元乙丙橡胶软管泵,这种一般适用于绝大多数腐蚀性的化学物质和无机物,内衬橡胶层由三元乙丙橡胶构成,外层也是完整的三元乙丙橡胶。这样的软管具备很强的抗化学腐蚀的特性。以及CSM软管泵,它适用于特别腐蚀性的化学介质,如:强氧化溶剂。软管的内层是CSM,外层是天然橡胶。运行温度达到85℃/185°F。

There is also a food-grade rubber hose pump. Its rubber layer must meet food hygiene requirements, and it must also meet EHEDG or other sanitary requirements. There is also a EPDM hose pump, which is generally suitable for most corrosive chemicals and inorganic materials. The inner rubber layer is composed of EPDM rubber, and the outer layer is also a complete EPDM rubber. Such hoses have strong chemical resistance. And CSM hose pump, it is suitable for particularly corrosive chemical media, such as: strong oxidizing solvents. The inner layer of the hose is CSM and the outer layer is natural rubber. Operating temperature reaches 85 ° C / 185 ° F.

众所周知软管泵在运行时,是通过一根U型附有弹性的橡胶软管来完成输送。今天小编需要强调的是,软管存放时间不宜过长,一般以一年为限。在停工期间,对装有软管的泵,若长期不用,每隔一个月需转动泵一次。以免压辊长时间压在泵管的某一处,减弱管子回弹性,影响其流量的输送。

It is well known that when the hose pump is running, it is conveyed through a U-shaped rubber hose with elasticity. Today the editor needs to emphasize that the storage time of the hose should not be too long, and it is generally limited to one year. During the shutdown period, if the pump is equipped with a hose, if it is not used for a long time, the pump needs to be rotated every other month. So as not to press the roller for a long time at a certain position of the pump tube, it will weaken the resilience of the tube and affect its flow rate.